What is a skateboard truck?

Skateboard trucks are the pivoting metal components that attach to the bottom of the deck and controls the turning. Trucks are what connect the wheels to the deck and give the wheels an axle to rotate on. A skateboard needs 2 trucks; all trucks sold by TGM Skateboards are sold in pairs (2 trucks). When choosing trucks, pick a pair with an axle width as close to the width of your deck that you can.

To see what trucks we have in stock, click here

How do trucks work?

Skateboard trucks feature a couple components that can cause them to work a certain way. Understanding how a truck works will help you decide on what trucks are best for you.

Components

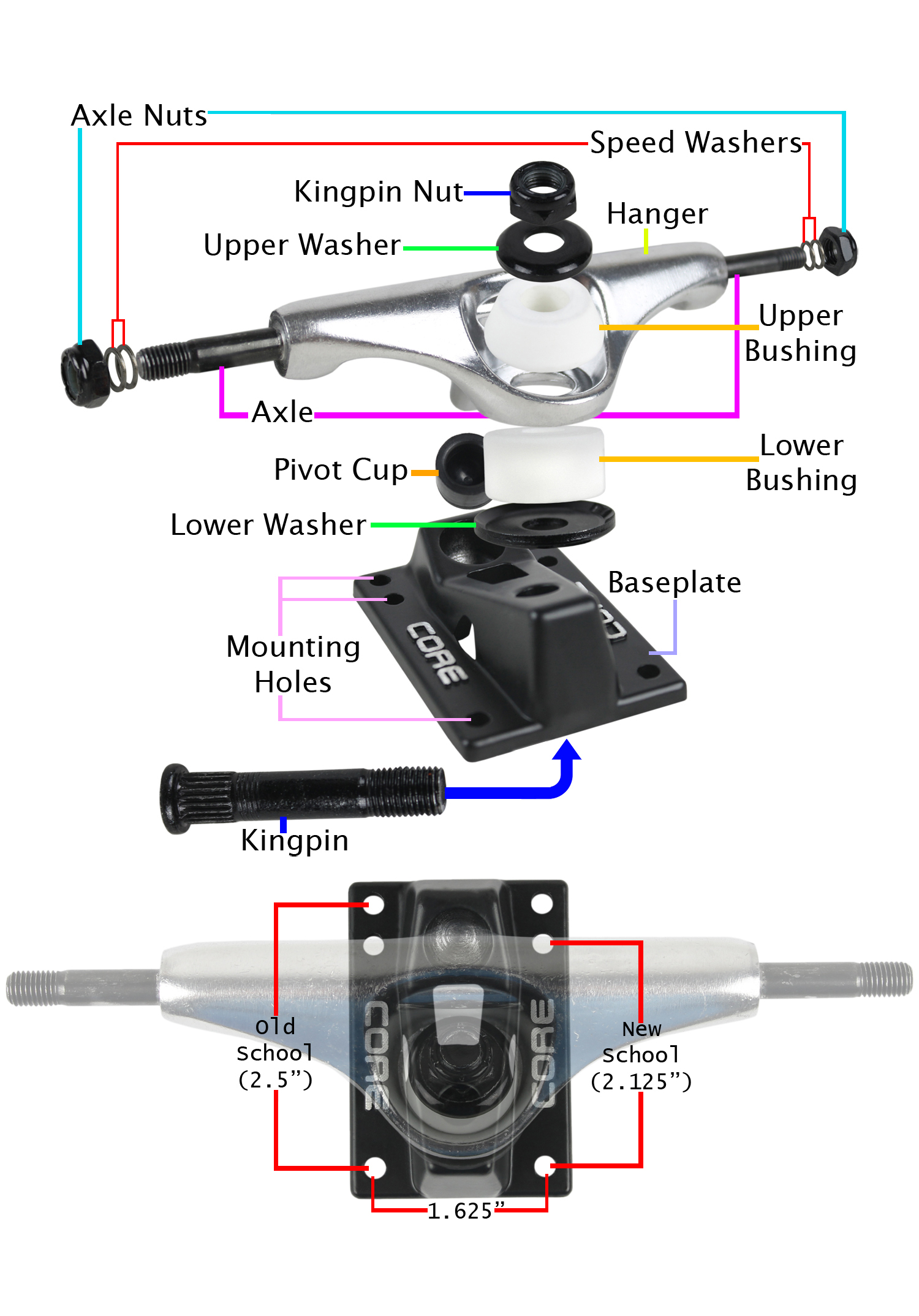

Axle: The long rod that runs through the hanger for the wheels to attach to. There is threading at the ends of the axle for nuts to attach to and keep the wheels in place. In some cases, companies will use a hollowed axle to lower the overall weight of the truck, but this does not make the truck any weaker.

Hanger: The triangular piece of metal that the axle runs through. It is the “upper” part of the truck and has an indentation for the bushings to rest in. This is usually the piece that companies will paint or apply graphics to give them a unique look.

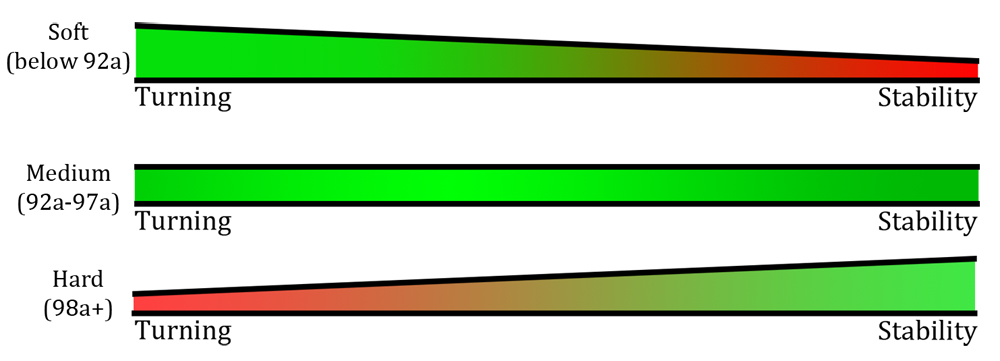

Bushings: The urethane rings that controls the boards’ ability to turn and pivot. The softer the bushing the more turn/ less stability, the harder the bushing the less turn/ more stability. There are always 2 bushings (one on top of the hanger & one under the hanger) and 2 washers to keep them stable (one on top of the upper bushing and one under the lower bushing). The hole down the center of the bushing is for the kingpin to run through.

Kingpin: The large bolt that keeps the truck together. It goes through the bottom of the baseplate, runs through the bushings, and goes through the top of the hanger where it has a nut to keep the truck together. In some cases, companies will use a hollowed kingpin to lower the overall weight of the truck, but this does not make the truck any weaker.

Baseplate: The bottom of the trucks, which is for mounting the truck to the deck. The baseplate is usually where you will find the name of the brand. It features mounting holes for the hardware to go through (4 - 6 holes). The extra 2 hole in a baseplate with 6 holes are for old school skateboard decks.

Pivot Cup: The small urethane cup that fits in an indentation in the baseplate to help the trucks turn. They will eventually wear down and make the trucks more unstable so it is important to keep an eye on this part. For the most part, this part is a universal fit and is a cheap piece to replace.

Note that not all trucks feature 6 holes, so make sure that if there are only 4 holes, that the trucks will fit your deck before buying.

Metal

- Aluminum: Aluminum is the industry standard for skateboard trucks. This is the most common alloy on the market right now.

- Magnesium: Magnesium trucks are known for being a lighter truck than most aluminum trucks.

- Titanium: Titanium is the strongest/lightest metal used in the production of skateboard trucks. This is a premium quality truck so it will increase the price tag but this is a great choice for someone who is looking for a pair of trucks that will last long and won’t weigh their board down.

Hollow vs Solid

Hollow skateboard trucks refer to having a hollow axle and/or hollow kingpin. This makes the truck lighter than its solid counterpart. It makes the trucks lighter without compromising the strength of the trucks. This is considered a luxury feature and will increase the price tag of a pair of trucks. This is only a concern of someone who is looking to make a super lightweight skateboard.

Bushings

Bushings are the urethane rings that controls the boards’ ability to turn and pivot. This is the most common thing skaters change about a pair of trucks when they buy them. The softer the bushing the more turn/ less stability, the harder the bushing the less turn/ more stability. Anything with a durometer (hardness) less than 92a is considered soft. A medium durometer would be from 92a-97a. A hard durometer would be anything from 98a and up. Durometer is also determined by weight. Heavier riders are more likely to choose harder bushings.

To see what bushings we have in stock, click here